News Center

Recommending Products

Contact: Mr. Jin

Tel: 13901575780

0512-52428686

Contact: Mr. Zha

Tel: 13913639797

0512-52422071

Address: No. 59, Huyi Road, Liantang, Shanghu Town, Changshu City, Jiangsu Province.

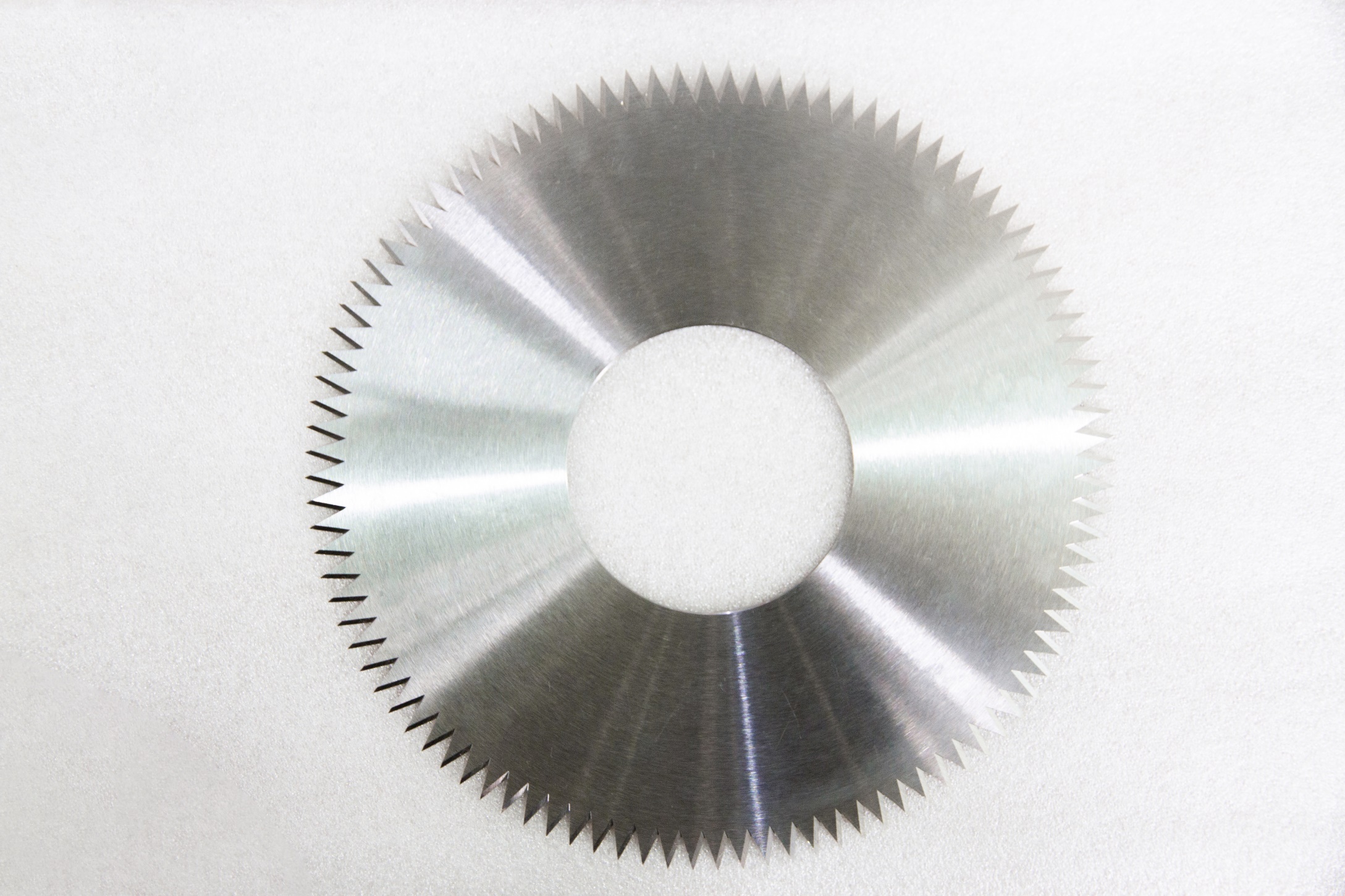

Application of High Speed Steel Sharp Angle Knife in the Mechanical Processing Industry

1. Milling applicationSources:www.cssjlgj.com | PublishDate:2024.11.13

Contour milling: High speed steel sharp angle cutters are very effective in milling the contour of parts. For example, when processing molds with complex shapes, such as the contour of injection molds, sharp edged knives can correctly mill along the designed curve. Due to its sharp blade tip, it can mill clear edges and correct details, which is crucial for manufacturing high-precision molds. It can enter narrow grooves and corners to achieve smaller radius turns, ensuring that the shape accuracy of the mold meets the design requirements.

Step milling: When milling step structures, high-speed steel sharp angle cutters can effectively control the height and flatness of the steps. For example, in the machining of mechanical parts, for bases with different height planes, sharp edged knives can control the height error of each step within a very small range through correct axial and radial feed. And it can maintain good surface quality during the milling process, reducing subsequent precision machining processes.

2. Turning machining applications

Detail machining in external turning: High speed steel sharp angle cutters are very useful for machining surfaces with special requirements when turning external circles. For example, when turning an outer circle with keyways or splines, a sharp edged tool can be used to machine the edges of the keyways or splines after turning the main outer part, making the edges sharp and the dimensions correct. Because of its small blade angle, it can better adapt to the processing of these special structures and avoid damage to adjacent parts during the processing.

The finishing work of inner hole turning: When turning inner holes, especially for blind holes with precision requirements, high-speed steel sharp angle cutters can be used for machining the bottom and edges of the holes. For example, when machining the inner hole of a hydraulic cylinder, after completing the main inner hole turning with ordinary cutting tools, a sharp angle knife can be used to process the corners of the hole bottom to make it smooth and even. At the same time, it can also be used for precision machining such as chamfering the edges of the inner hole to improve its quality.

3. Drilling and machining applications (special circumstances)

Expanding and countersunking: In some special drilling processes, high-speed steel sharp edged knives can also play a role. When it is necessary to enlarge an existing hole and require the enlarged hole wall to have the correct right angle or to chamfer the hole at a specific angle, a pointed angle knife can be used as an auxiliary tool. For example, in the machining of positioning holes for assembly, after enlarging the hole, a sharp edged knife is used to countersunk the correct 90 ° chamfer, in order to facilitate the installation and positioning of subsequent parts and ensure assembly accuracy.

4. Carving processing applications

Fast carving: High speed steel sharp edged knives are widely used in the field of mechanical carving. In the production of nameplates and signs, it can be used to carve text, patterns, trademarks, and other content. Due to its blade tip's ability to accurately control the depth of carving and the width of lines, it is able to carve very delicate and realistic patterns. For example, when making metal crafts, sharp edged knives can carve complex patterns and textures on the metal surface according to design requirements, making the crafts more artistically valuable.